Precision Plastic Injection Mouldings Blade Wheel Part For Air Cleaner

This precision-engineered plastic blade wheel component is specifically designed for air cleaner applications, manufactured through advanced injection molding technology. Crafted with high-grade polymers, each blade is meticulously formed to ensure optimal air flow and consistent performance. The injection molding process guarantees exceptional dimensional accuracy and structural integrity, while maintaining uniform thickness across all blades. This component features smooth surfaces and precise tolerances, making it ideal for efficient air circulation and filtration systems. The durable plastic construction offers excellent resistance to wear, corrosion, and environmental factors, ensuring long-term reliability. Perfect for integration into various air cleaning devices, this blade wheel delivers consistent rotation and balanced operation. Our rigorous quality control processes ensure each piece meets strict manufacturing standards, making it a trusted choice for air cleaner manufacturers seeking reliable, cost-effective components.

- Overview

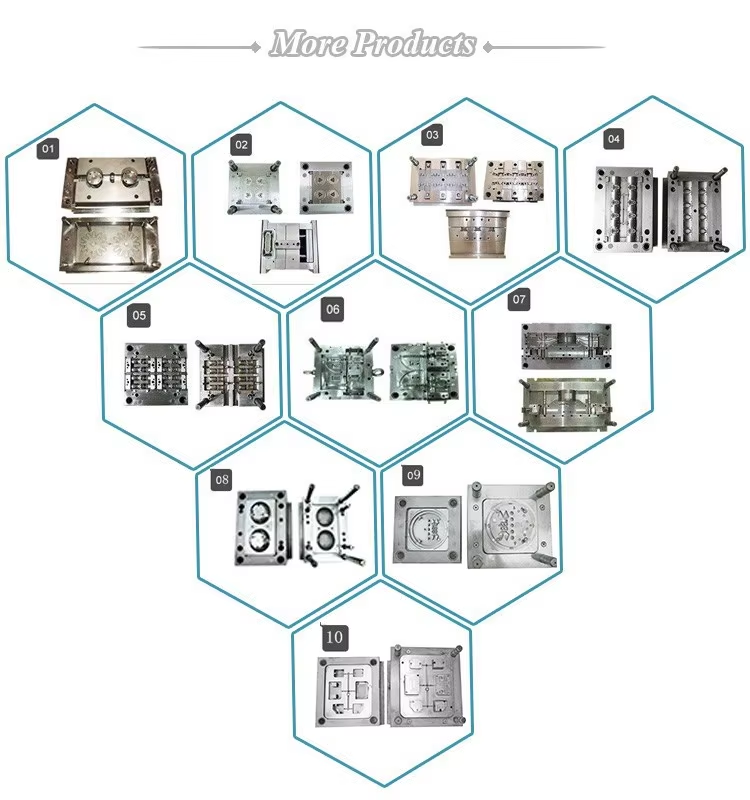

- Recommended Products

| 1 | Plastic injection Mould standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM STANDARD |

| 2 | Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

| 3 | Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| 4 | Hardness of steel | 46~56HRC |

| 5 | Material for Slider ,Lifter and all sub insert use | 1.2767 HRC |

| 6 | Cavity | Single-cavity ,Multi-cavity |

| 7 | A surface request | EDM & High Polish |

| 8 | Gate | Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

| 9 | Maximum mould size | 1500*1500 mm |

| 10 | Mould life time | 500000~+1,000,000 shots |

| 11 | Quality | ISO9001-2008 certification |

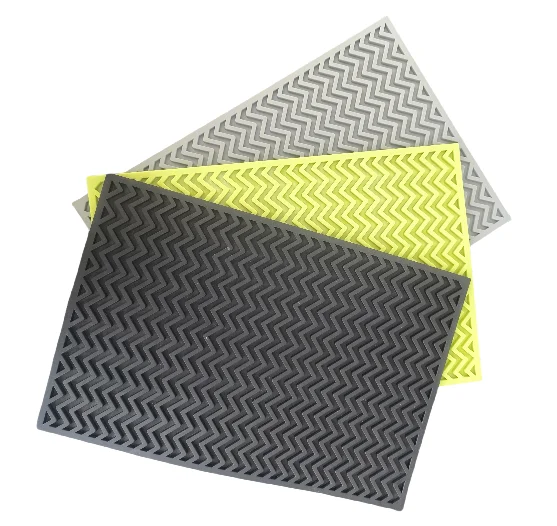

| 12 | Product material | PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

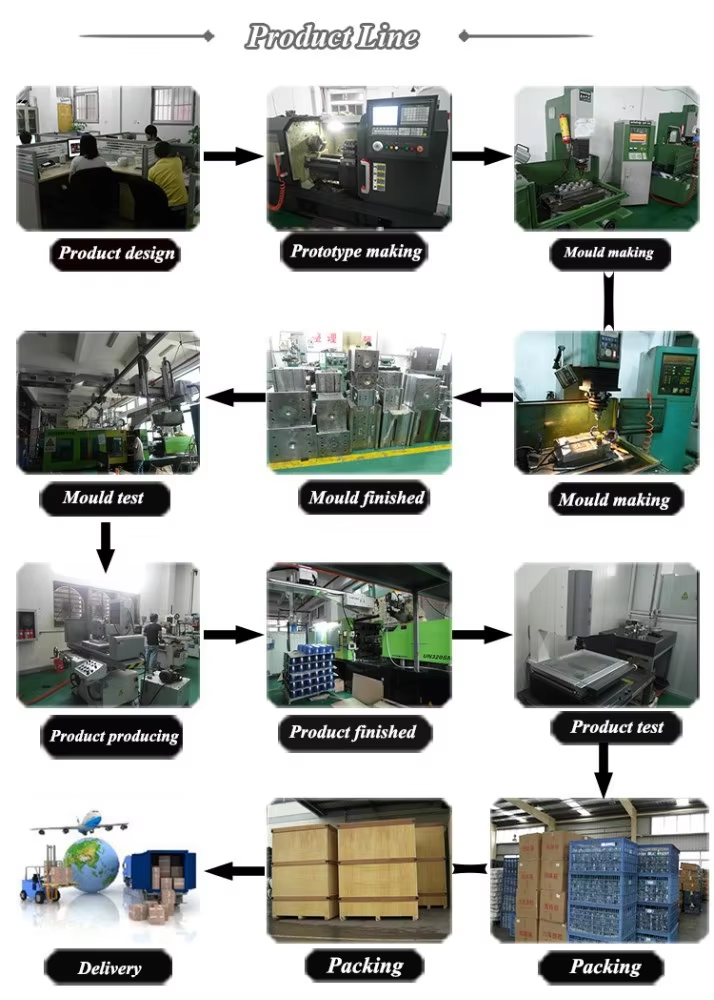

| 13 | Lead time | 4~7 Weeks |

| 14 | Package | Wooden/Plywood case for tool ,PE bags add export carton for parts |

| 15 | Payment terms | T/T |

| 16 | Trade terms | FOB XIAMEN |

| 17 | Export country | Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

| 18 | Value-added service | Polish,texture,painting,screen printing,turnkey project |

| 19 | As a professional Plastic Injection mould ,Die casting Mould & Moulding manufacturer, our range products are covered from Automobile,Electronic,Industrial,Household,Medical,Sport,Office etc | |

| 20 | Clients project's 3D drawings or samples are highly appreciated | |

(1)Quality control and Technology improvement

Have 6 members in our Q&C Department.And passed ISO9001:2008 in the year of 1997

(2)Competitive price

unique raw material purchasing channels, warehouses, transportation systems, packing workshops and good management, to guarantee our price competitive.

(3)On time delivery date

Our qualified and professional foreign trade team will help you to keep the delivery date on time.

(4)Good OEM&ODM Service

we provide OEM&ODM service of kinds of moulds and products.We sign confidential agreements with all our OEM&ODM customers.

(5)Best after-sales-service

Please contact our after-sales service department in time, they are patient and kindhearted, they will help you, Tel: 0086-592-6259391

(5)Factory square and plant assets

With a plant assets of 1million US dollars,our company covers an area of 4,000 square meters.

(6)Company

Established in 1997,specializes in the research and development all kinds of moulds for plastic products.

1. 18 years rich experience on mold industry and a wide range of products

2. Main market covers North America, Europe, Australia, Middle East and South-east

3. Outstanding merchandise and considerate 24 hours on line customer service

4. On time delivery and satisfy all your requests

5. One-stop service

Q: Does your company make mould by yourself?

A: Yes, we are manufacturer with more than 25 years of molding experience.

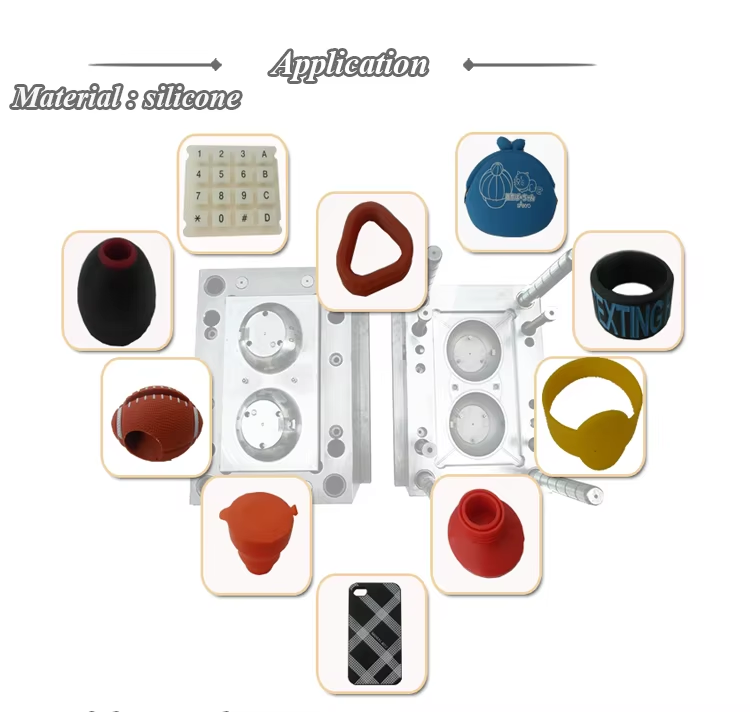

Q: How many kinds of moulds can you make? Only make the injection moulds?

A: We can make many kinds of moulds, such as plastic injection moulds, blowing moulds, stamping moulds, die casting moulds and silicone rubber moulds. Besides, we also can produce the final parts for you.

Q: What’s the software you will use to check the drawing? And what’s format of drawing you can check?

A: Our designers and engineers all use AUTO CAD and Soliworks software to check 2D and 3D drawings.We can check the drawings with PDF, AI, DWG (CAD) and STP (3D) or IGS (3D) formats.

Q: Will you send me the free sample?

A: Yes, but you should charge the freight by yourself. We can return the fee if you place a bulk order.

Q: How to pack the moulds and products?

A: For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack into non-fumigation wooden case. And as to products, we will pack into standard export cartons or as per customer’s request to pack.