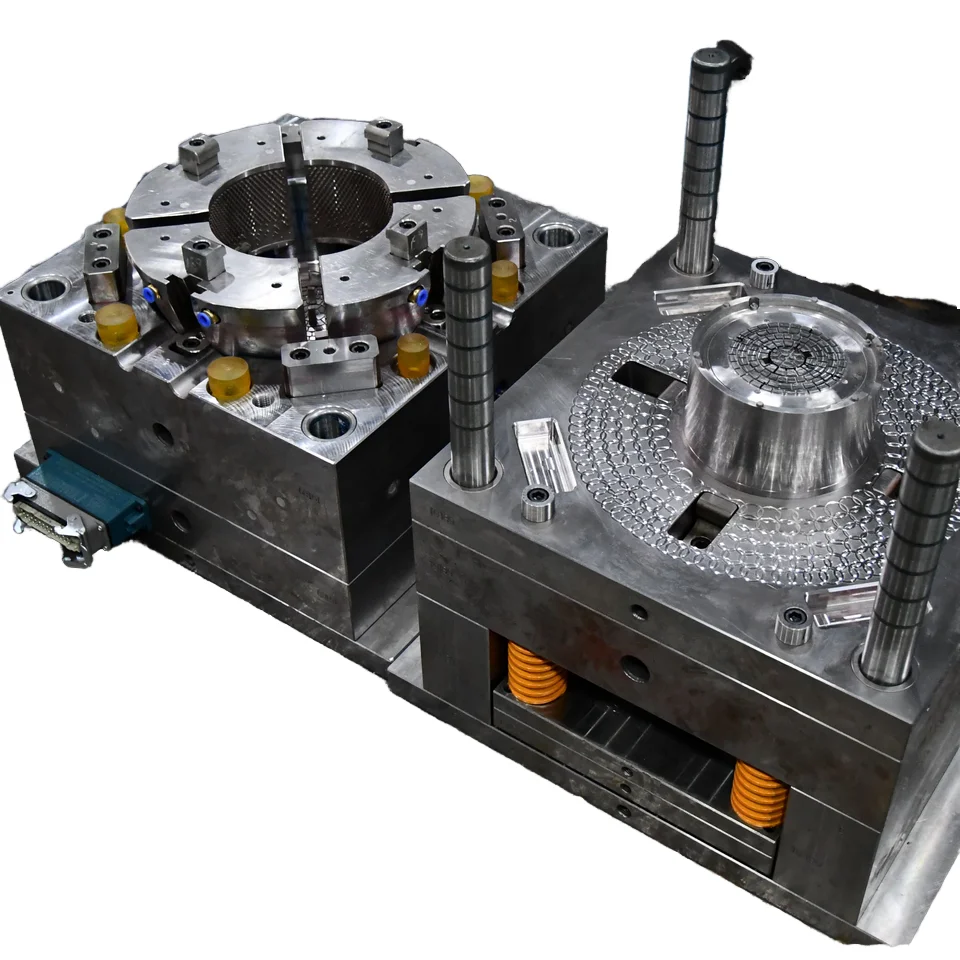

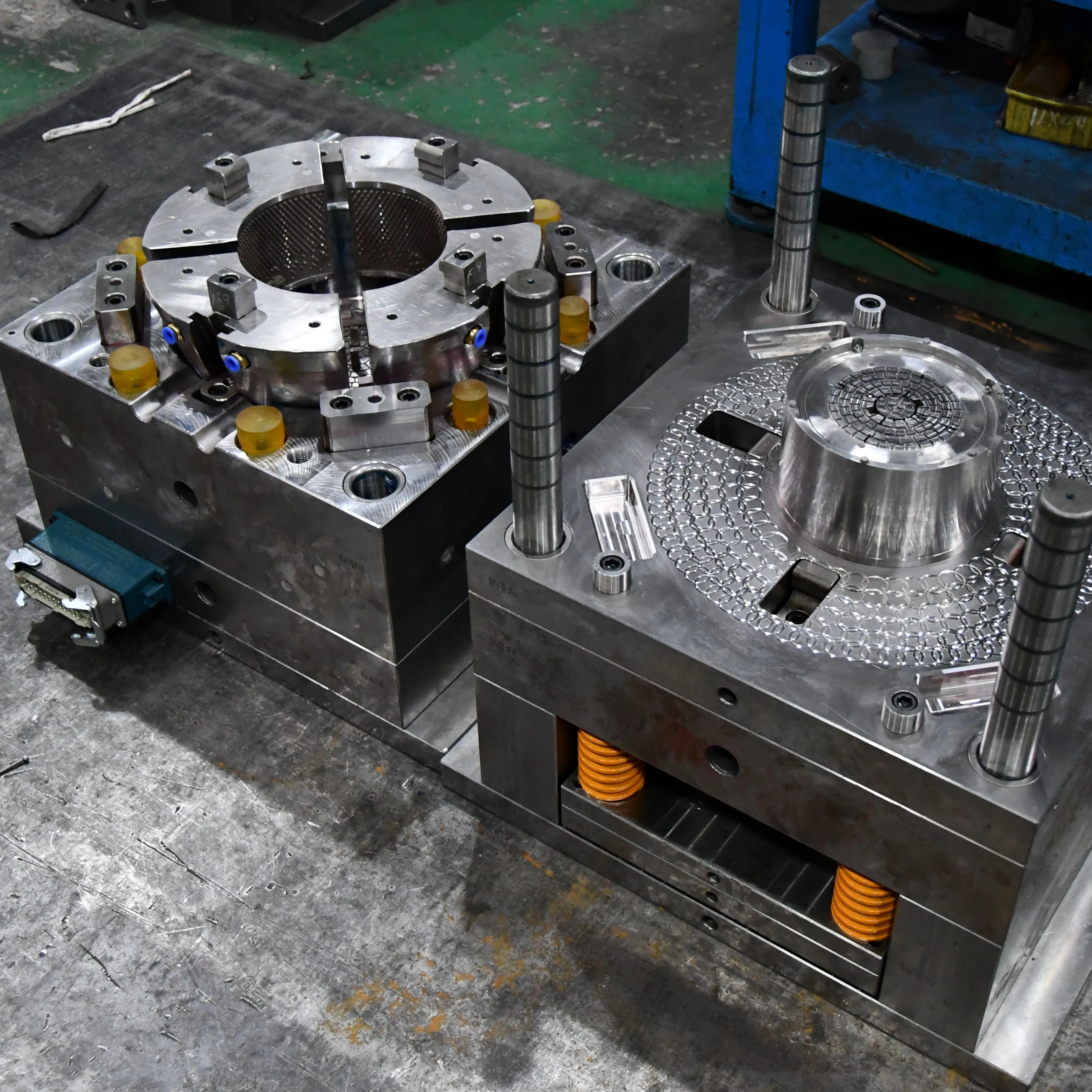

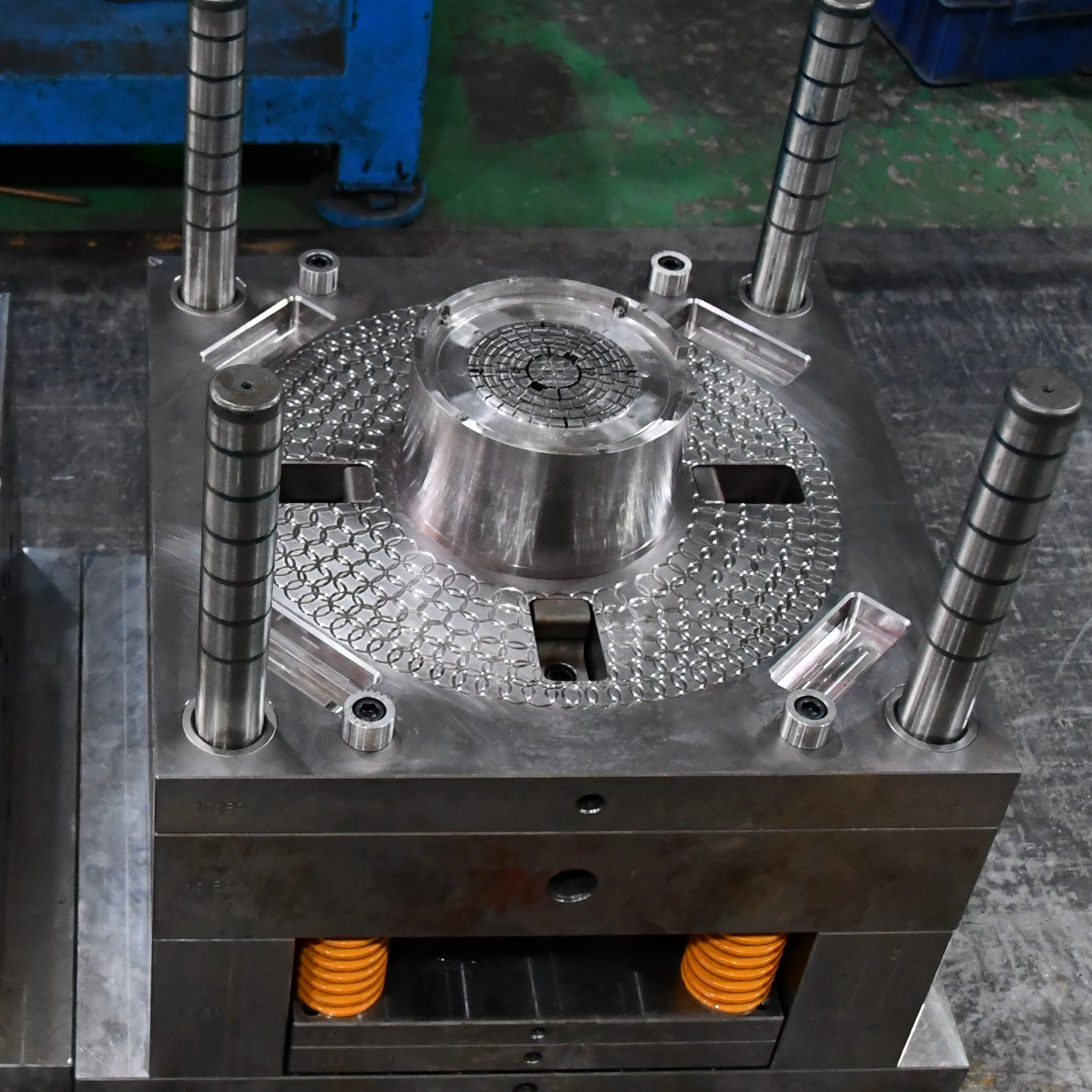

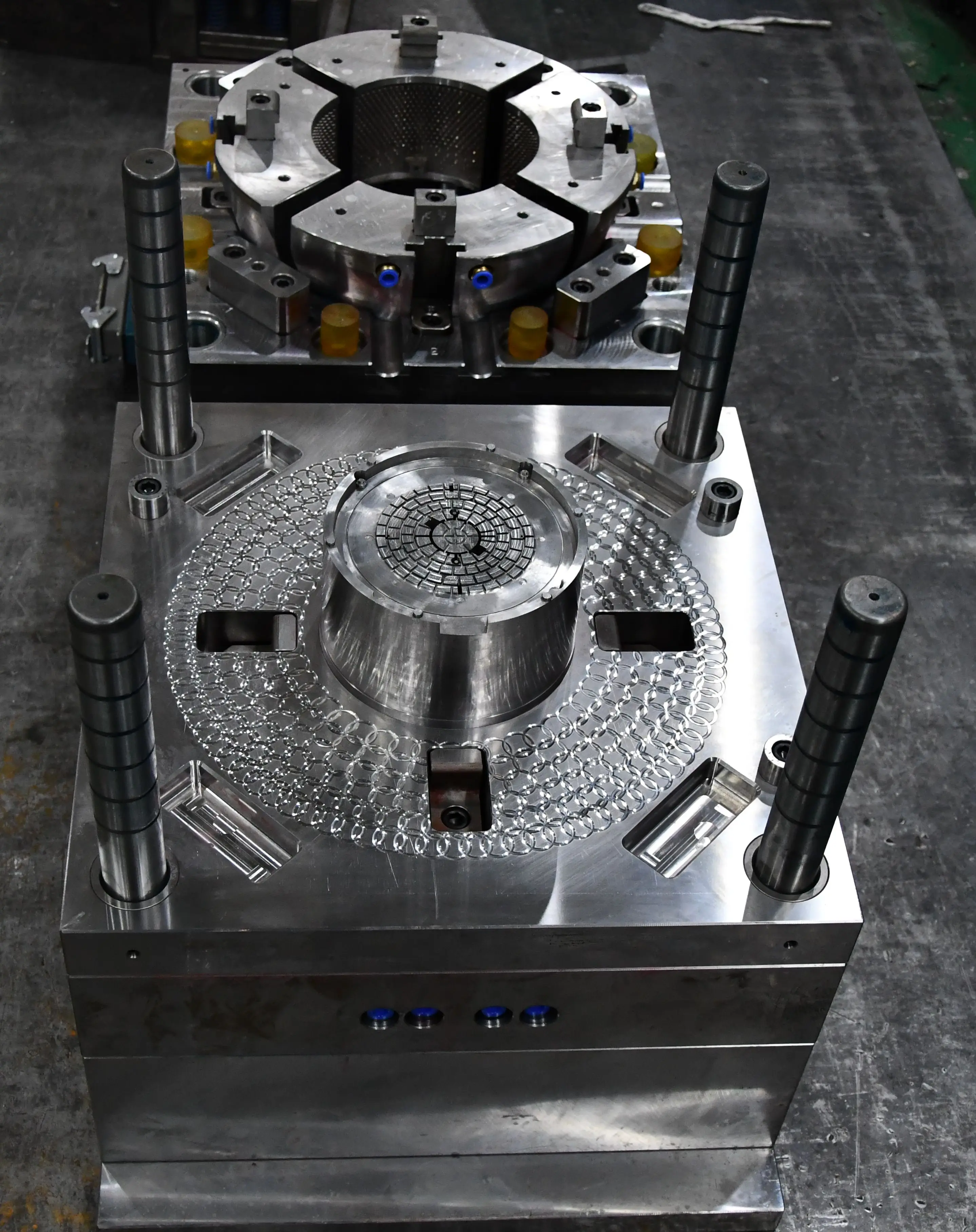

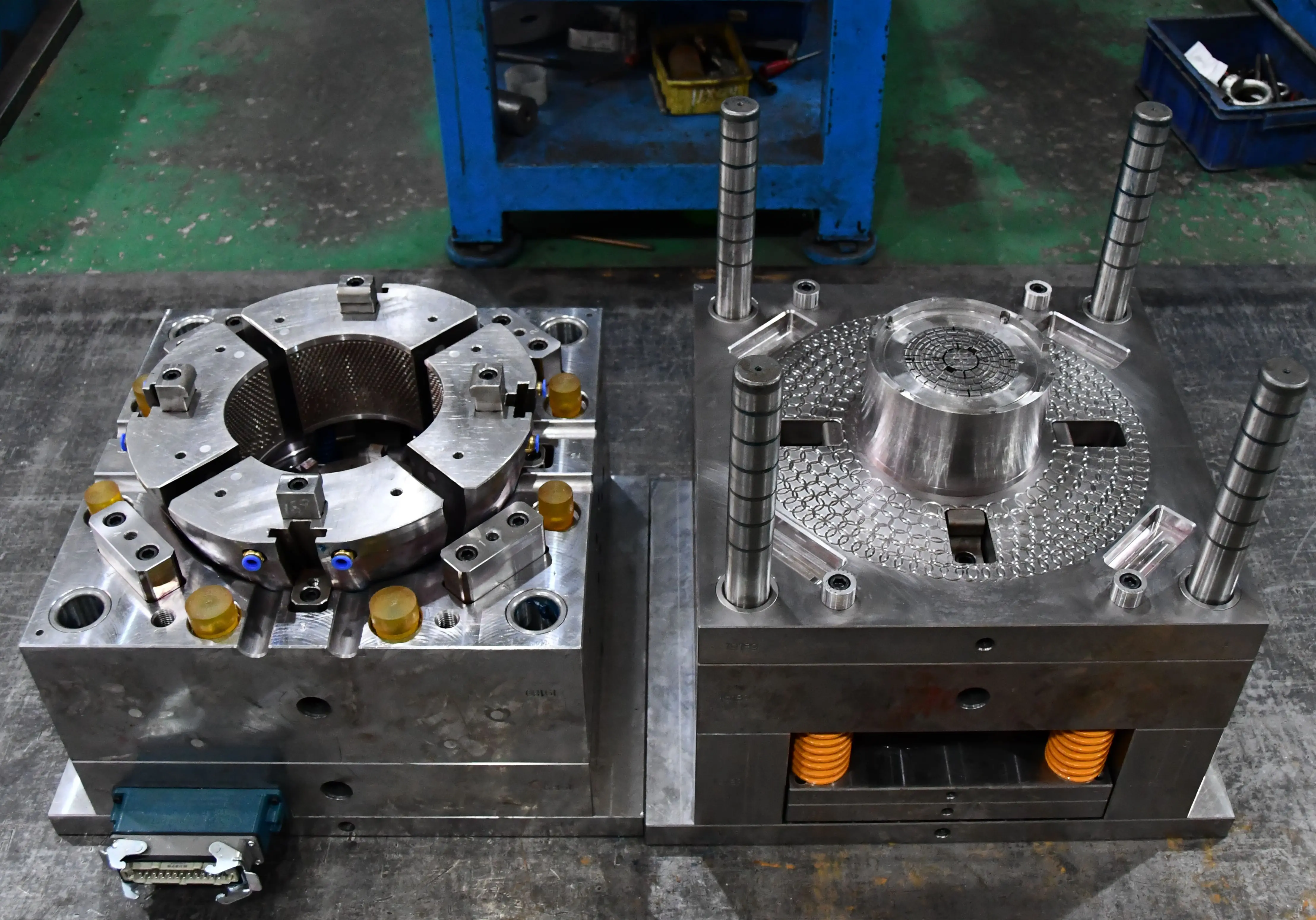

High Quality ABS and PC Injection Mold for Home Appliance Housing CNC Hot Runner Plastic Parts P20 Mould Material

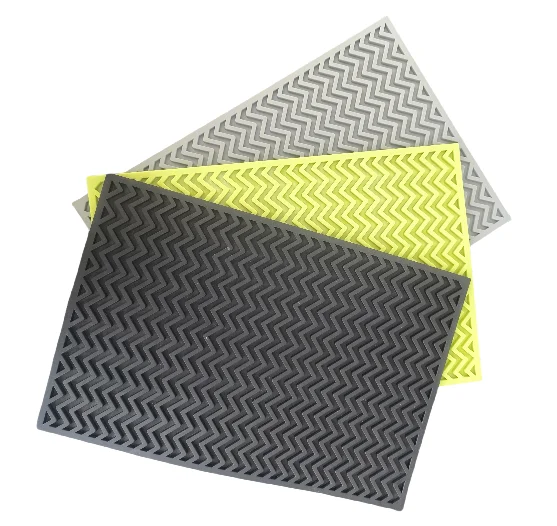

This premium injection mold solution is specifically designed for manufacturing high-quality home appliance housing components using ABS and PC materials. Crafted from durable P20 mold steel, this professional-grade mold features an advanced hot runner system that ensures optimal material flow and minimizes waste. The precision CNC machining delivers exceptional accuracy and surface finish for consistent, high-quality plastic parts production. Perfect for both high and low-volume manufacturing runs, this mold is engineered to produce dimensionally stable housings with excellent aesthetic appeal and structural integrity. The design accommodates efficient cooling and easy maintenance, resulting in reduced cycle times and extended mold life. Ideal for producing various home appliance enclosures, panels, and covers, this versatile mold delivers reliable performance and cost-effective production capabilities for demanding manufacturing environments.

- Overview

- Recommended Products

Enhanced Efficiency and Productivity

Hot runner injection molds utilize advanced hot runner technology to significantly improve production efficiency. By reducing cooling time and optimizing melt flow paths, the product molding cycle is shortened, making it suitable for large-scale, high-frequency production needs.High Precision and Stability

The hot runner design is highly precise, ensuring product consistency and stability. The mold structure is well-designed to effectively prevent deformation and flow marks, guaranteeing that the finished product meets high-quality standards.Material Savings and Cost Reduction

Hot runner technology optimizes melt distribution, reducing material waste and lowering production costs. It is ideal for manufacturing high-quality, thin-walled products.Versatility for Multiple Materials

Whether it's PP, PE, ABS, or PC materials, hot runner injection molds can operate stably, meeting the diverse needs of different customers.Eco-Friendly and Energy Efficient

The energy-efficient hot runner design reduces energy consumption, meets environmental requirements, and complies with international quality certification standards.Customization Services for Tailored Solutions

Customized mold design and manufacturing services are provided according to customer needs, meeting specific product requirements and helping customers stand out in the market.

| item | Mould |

| Place of Origin | China |

| Shaping Mode | Plastic Injection Mould |

| Brand Name | XTL |

| Product Material | Plastic |

Xiamen Xintonglian Plastic Co., Ltd., established in 1997, specializes in the design and fabrication of various molds and the production of finished products. Our factory, strategically located in Xiamen City, Fujian Province, China, benefits from the city's coastal location and its convenient sea, land, and air transport links.

Continuing our expertise for 24 years, we are dedicated to the design and production of injection molds, blowing molds, and silicone rubber molds. We create a wide range of products for domestic and international clients, catering to industries as diverse as kitchenware, pet products, electrical appliances, electronic casings, mobile phone accessories, computer accessories, office products, sanitary ware, medical equipment accessories, automobile parts, circuit connectors, and drainage pipeline accessories. Our clients span the globe, including regions in Europe, North America, South America, and Southeast Asia.

Our company's wealth of experience in mold manufacturing and forming processes is bolstered by a skilled, experienced engineering team. We are equipped with state-of-the-art facilities, including a complete range of mold processing equipment, injection molding machines, and silicone rubber vulcanization equipment. We offer a comprehensive 'one-stop' service, encompassing design, 3D printing samples, mold development, and production with packaging.

If you have ideas, samples, or drawings, we are equipped to manufacture superior molds and produce high-quality products tailored to your needs. We invite you to visit and inspect our company at any time, and we are eager to continue improving through your support.

1. who are we?

We are based in Fujian, China, start from 1997,sell to Domestic Market(79.00%),North America(13.00%),Eastern Europe(3.00%),Western Europe(2.00%),Oceania(1.00%),Mid East(1.00%),Southeast Asia(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Plastic Injection Mold, Plastic Products, Silicone Rubber

4. why should you buy from us not from other suppliers?

We're a professional manufacturer since 1997, and we have rich experience on mould industry, our engineers have more than 20 years technical experience. Except for the moulds, the finished products production and assembly are also available.

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW,Express Delivery;

Accepted Payment Currency: USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Cash;

Language Spoken: English,Chinese