Essential Plastic Injection Molding Electric Propeller Parts for RC Airplane Glider Aircraft Fixed-Wing Drone

This high-quality plastic injection molded propeller is expertly designed for RC airplane enthusiasts seeking reliable performance and durability. Precision-engineered using advanced injection molding technology, these essential propeller parts deliver optimal thrust and efficiency for your fixed-wing aircraft, glider, or drone. The carefully balanced design minimizes vibration while maximizing aerodynamic efficiency, ensuring smooth and stable flight characteristics. Made from durable plastic material that offers an excellent strength-to-weight ratio, these propeller parts are built to withstand regular use while maintaining their structural integrity. Easy to install and compatible with most standard RC electric motors, these propellers are an ideal choice for both beginners and experienced pilots looking to maintain or upgrade their aircraft. Whether you're flying for recreation or sport, these propeller parts provide the reliable performance you need for successful flights.

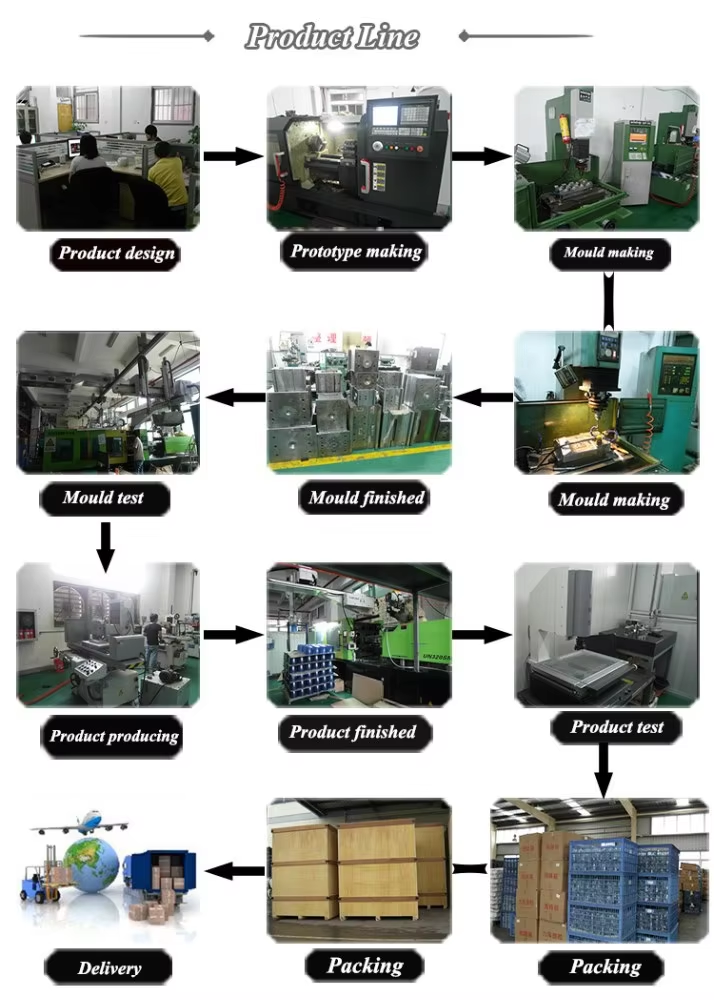

- Overview

- Recommended Products

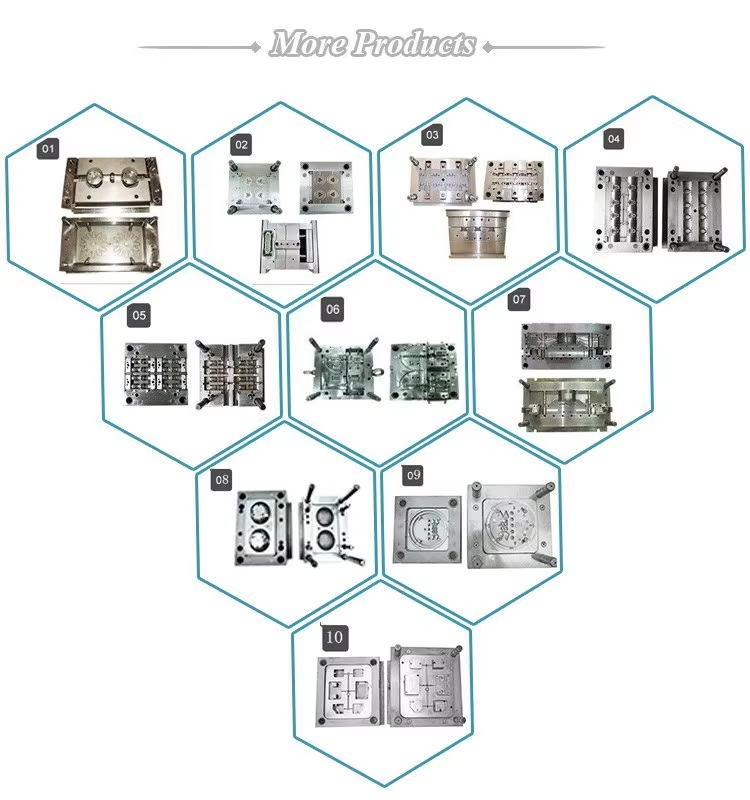

Plastic injection mold standard |

HASCO,DME,MEUSBURGER,JIS,CHINA LKM STANDARD |

Mould/mold base |

LKM&Hasco&DME standard (A,B plate 1730,2311, 2312,P20 ) |

|

Material main core and cavity insert |

DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

Hardness of steel |

4656HRC |

|

Material for Slider ,Lifter and all sub insert use |

1.2767 HRC |

Cavity |

Single-cavity ,Multi-cavity per request |

A surface request |

EDM & High Polish |

Gate |

Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

Maximum mould size |

1500*1500 mm |

Mould life time |

100,000-5,000,000 shots |

Quality |

ISO9001-2015 certification |

Product material |

PA,PA6/66+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

Lead time |

4~7 Weeks |

Package |

Wooden/Plywood case for tool ,PE bags add export carton for parts |

Payment terms |

T/T |

Trade terms |

FOB XIAMEN |

Export country |

Europe countries,USA,Mexico,Australia ,Middle-east , Asia etc |

Value-added service |

Polish,texture,painting,screen printing,turnkey project |

(1)Quality control and Technology improvement

(2)Competitive price

(3)On time delivery date

(4)Good OEM&ODM Service

(5)Best after-sales-service

(6)Company

Q: What kind of product can you make?

A:We offer the design and manufacture of plastic injection molds and the injection of the plastic parts.

Q: How many kinds of moulds can you make? Only make the moulds?

A: We can make many kinds of moulds, such as plastic injection moulds, blowing moulds, stamping moulds, die casting moulds and silicone rubber moulds. Besides, we also can produce the final parts for you.

Q: What’s the software you will use to check the drawing? And what’s format of drawing you can check?

A: Our designers and engineers all use AUTO CAD and Soliworks software to check 2D and 3D drawings.We can check the drawings with PDF, AI, DWG (CAD) and STP (3D) or IGS (3D) formats.

Q: Will you send me the free sample?

A: Yes, but you should charge the freight by yourself. We can return the fee if you place a bulk order.

Q: How to pack the moulds and products?

A: For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack into non-fumigation wooden case.And as to products,

we will pack into standard export cartons or as per customer’s request to pack.